By Gustavo Teixeira, Theresa Heitman and Adam Hunt

Crop breeding programs are setting an example for how to examine and improve their work – while embedding this process into organizational culture. It's all to better meet the needs of their customers, namely breeders, farmers and donors. Here, experts walk through the process, and examine a CGIAR rice breeding case study from the International Rice Research Institute (IRRI).

In order to grow, an organization needs a process to examine its processes. It needs to inspect its inefficiencies, moderate its mistakes, and tackle its time-wasters. But improving our processes doesn’t just elevate the work itself, it means better results for customers.

Given this customer-centric impact, it’s a good idea to adopt this not as a single event, but as a permanent mindset. Actually, it’s more than just a good idea for agricultural research organizations. One of our key customers – funders – are demanding this kind of continuous improvement. Our success is depending on it.

Take the global agricultural R&D network CGIAR. To meet the needs of funders and end users such as smallholders and governments, we are unifying and improving our systems. One CGIAR aims to defragment the research agenda and ensure its network of research centers’ scientific innovations are “deployed faster, at a larger scale, and at reduced cost, having greater impact where they are needed the most.”

Training at IRRI's Seed Health Unit. Source: IRRI

Aligned with this, CGIAR Excellence in Breeding (EiB) is working with our crop breeding partners to drive forward modernized breeding operations. We want to help them integrate the latest breeding technologies and practices in ways that result in significant increases in genetic gain per dollar invested. Achieving this means farmers in the developing world will adopt better varieties of crops, faster.

This vision doesn’t just mean a change here or there. It demands a “continuous improvement” (CI) process that moves us toward operational excellence – in perpetuity, as part of a new culture. CI is a long-term business strategy that can, with support from leadership, develop a mindset of daily improvement where everyone in the organization is making their processes better every day, and seeking to deliver value to the customer.

The most famous example here is the car manufacturer Toyota. Toyota devised the now famous “just in time” inventory approach by examining the space it wasted on storage, the time it wasted in managing inventory, and the money tied up in keeping inventories high. Using American supermarkets as a model, they moved to a system where inventories were replenished only when needed, and only when triggered by the system. This approach helped transform the company into an elite auto manufacturer, making big profits for its shareholders and delivering quality, low-priced cars to its buyers.

The Lean Methodology: a strategy for growth and customer satisfaction

To reach such achievements for your organization, a few methodologies exist. We use the Lean Method, because it is widely adopted, relatively simple and fits the broad needs of breeding programs. It is a strategy for growth that earned its “lean” nickname because it eliminates waste while maximizing value to ‘customers’, which, for research organizations, could be down-the-line breeders, smallholders who use the end product, or even funders who expect a return on investment.

Lean requires the organization to always be customer-centric. And to ensure respect for all employees. This often takes cultural change – sometimes dramatically so. And it definitely needs leadership commitment.

To drive forward the principles of Lean, organizations follow five steps. In order to trial these steps with our partner International Rice Research Institute (IRRI), we tasked them with tackling three problems. These linked to program improvement plans all CGIAR breeding programs developed with support from EiB. One of the challenges they chose was a product delivery issue at their Los Banos facility: researchers complained that rice seed shipments were often delivered very late.

The team drilled down to the root cause of the late shipments using a method call Five Whys. They first asked why the shipments were late, then interrogated that response with another "why?". After five such Whys, they arrived at the root cause: inability to stop seed contamination. Field management at IRRI normally includes disease management and pest control activities, but these seemed ineffective or insufficient to meet the customer’s requirements, ultimately causing the late delivery of shipments.

Now IRRI is helping their customers, including their hybrid rice team, with a plan to optimize management to reduce the level of pathogen contamination of rice seeds produced. Here’s the Lean steps they are taking toward this goal:

1. Specify value: Determine how your customers define value

Specifying value means figuring out what customers are willing to “pay” for. In some cases, they pay with money to buy your product. Or if they are a donor, through money invested. Others pay with time spent. In the IRRI example, taking this step meant mapping out customers and their needs.

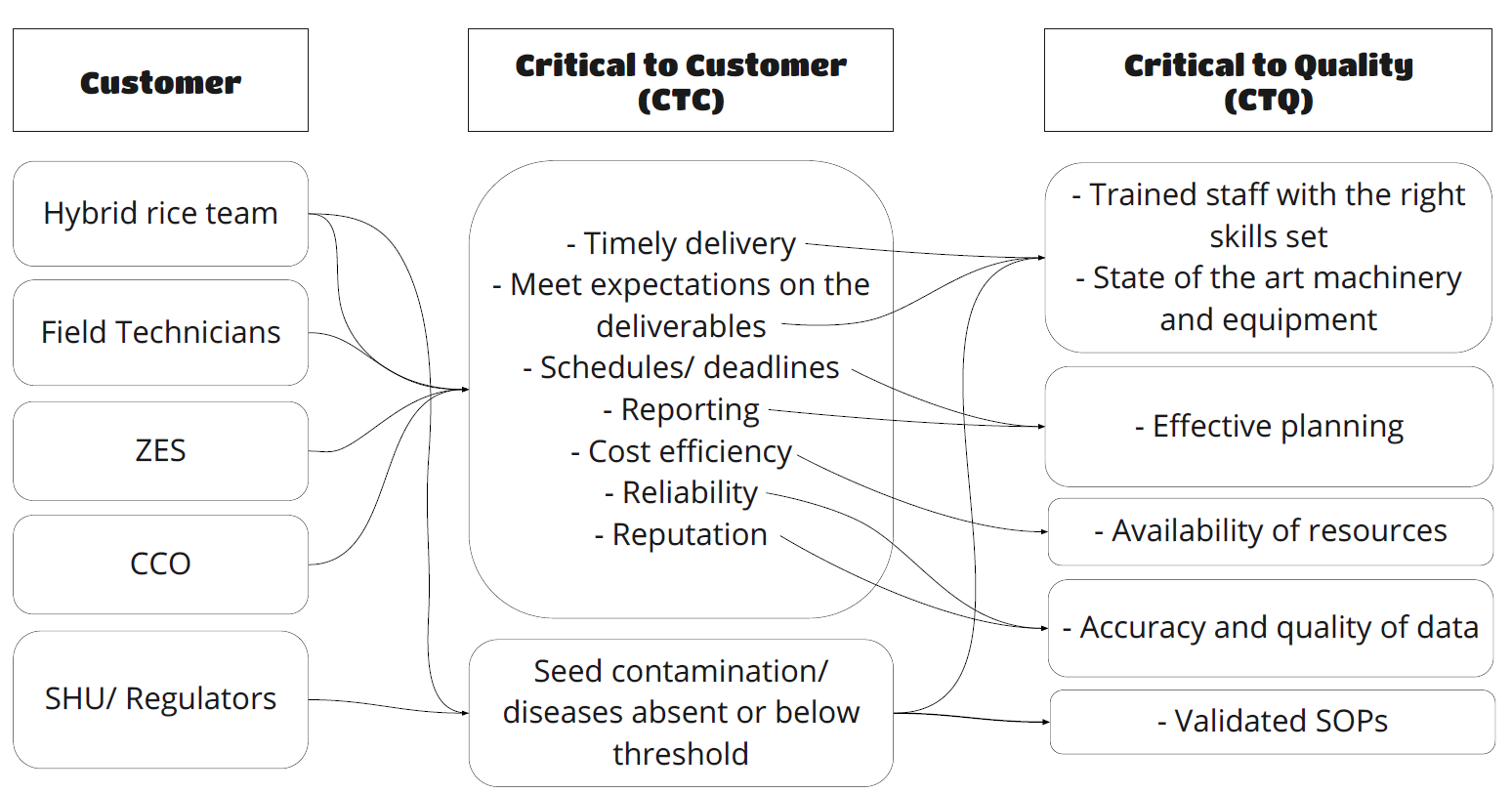

IRRI’s customers, it turns out, include more than just the hybrid rice team who use the seed in the laboratory. They also include the field technicians, regulators and administrators who are part of this service’s process. Next, the team determined what was critical to those customers, which included not just timeliness, but also cost, communications about status of the service, and, of course, having low seed contamination.

IRRI defines elements critical to their customers (CTC). Source: IRRI

2. Identify value stream: Map the activities that create value

Next IRRI set out to identify the steps in the value stream so that they could eliminate every step, action, and practice that does not help the process create value for the customers.

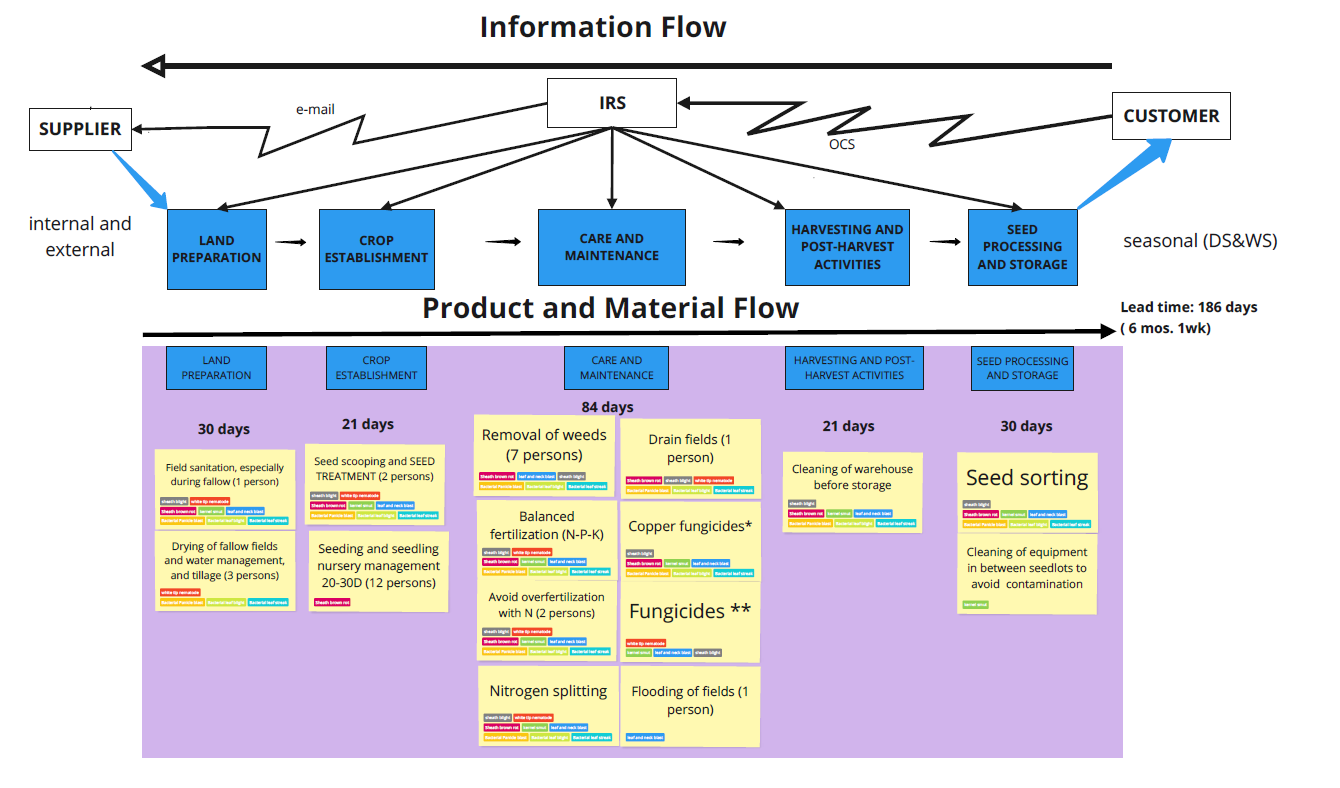

Rice seed production includes several sub-processes, starting with planning, through land preparation, field and crop management, seed quality management and, finally, seed distribution. IRRI mapped out this process, identifying Suppliers, Inputs, Process, Outputs and Customers (SIPOC). For example, seed quality management involves sampling, testing and storage. Its output is a label accurately describing seed health, which is used by its final customer, the hybrid rice breeders, who then use the data when selecting seeds for breeding.

Using Lean tools such as fishbone and spaghetti diagrams, the team then mapped out the flows of work and information, and the main factors contributing to the contamination of seeds by pathogens. They decided to target three areas: 1) lack of planning and scheduling of field activities across service units, 2) lack of disease management strategy and 3) failure to follow procedures.

IRRI 's value stream map showing material flow. Source: IRRI

3. Create flow: Ensure smoothly flowing processes

All steps in a process must be in a tight and integrated sequence so the product will flow smoothly to the customer. So, to create better flow, the IRRI team used their above analyses to design improvements to solve their root problem of seed contamination. The team will be implementing a disease management sampling plan which will include regular inspections for crop health, dry seed inspections, and routine seed health tests. They will be creating a service agreement and training plan to help contractors or external service suppliers improve their methods. And they’ll be training staff on quality control and process improvement with the aim of further developing the quality culture.

4. Enable pull: Help customers pull value from your activities

Once the process is flowing, allow customers to pull value from the next upstream activity. This means activities are executed if and when demanded by the customer. For IRRI, this means they will only produce the amount of seed needed by the breeders. In today’s process, they are producing more than they need because they do not have the confidence that seeds are free of diseases. Producing only what customers demand will free up a lot of resources – time and money.

5. Continuously improve: Have systems in place to ensure the process gets better and better

This is the core of the process. As these steps lead to greater transparency, managers and teams can eliminate further waste (non-value added activities), and pursue perfection through continuous improvement.

For IRRI, implementing an enhanced seasonal field management program, which includes proven pest and disease control activities, will improve the crop health status. This will result in better seed quality with shorter turnaround times. A problem will be solved, with the mechanisms in place to keep improving on this progress.

Crop health inspection at IRRI's facility. Source: IRRI

A template for CGIAR improvement

This initiative may serve as a template for IRRI and others in CGIAR. We’ve seen some success with CIMMYT, which, for example, used the system to transform a facility by getting rid of equipment that they didn’t need. This freed up space, created a more efficient facility, and served as an example of the kind of continuous improvement that CIMMYT is undertaking.

Ultimately, success can demonstrate the value of adopting a systematic approach to achieving excellence. Adopting continuous Improvement could mean a cultural transformation that brings CGIAR to the next level. For CGIAR research centers, that means not just satisfied funders and less stressed scientists, but farmers receiving the seeds, technologies and skills they need to meet our global food needs.

Resources:

- Download EiB's continuous improvement tools

- Recent EiB /AGG webinar gives an overview of Continuous Improvement concepts, along with real case studies from research and the private sector. : https://youtu.be/LWDs3fttlEM

---

Gustavo Teixeira leads the Operations and Phenotyping module for CGIAR Excellence in Breeding (EiB), Theresa Heitman is a Continuous Improvement Consultant at Experiential Excellence LLC, and Adam Hunt leads communications for EiB.

---

This blog reflects the information and views of the authors only. EiB and partners are supported by CGIAR Trust Fund Contributors, the Crops to End Hunger initiative, the Bill and Melinda Gates Foundation, GIZ, BMZ, USAID, UK Aid, ACIAR and other partners.

Comments

Embed works really well, like

Thanks. It is vital to know